The Torch Song

Live music is better than recorded music. It’s a given. Having that connection, where you’re sharing the same space as the artist is a unique experience that can’t be replicated on a plastic disc. To receive the gift from the giver personally is a moment of intimacy not possible if it arrives in a package in the mail. To be able to garner instantaneous gratitude, be it by applause, cheers or a smile is the reward that the artist lives for, else they wouldn’t be there. Showing appreciation for the gift returns the favour in kind. The performance feeds the audience, and vice versa.

Vinyl records hold the same sort of appeal that steel bicycles do; both materials revolutionised their respective industries and held the mantle of the best, the only choice, for decades. Then both were usurped by smaller, lighter composite materials and while the convenience and perceived performance they offered took over on a wholesale scale, a handful of purists held on to their Electric Ladyland limited edition LPs along with their Colnago Masters and Merckx Leaders. Vinyl may have been suddenly deemed cumbersome, inconvenient to use and harder to source, but it still offered a timeless sound quality that just had something about it, something that CDs and MP3s would struggle to achieve.

Same with steel bikes. There’s an indisputable and indescribable feeling that comes in the first few pedal strokes on a steel bike, and like pulling out that dog-eared copy of Hunky Dory, you know exactly what you’ll be getting, and you’re gonna like it. Picking up a hand-built bike from the person who made it is like going down to the studio to grab a signed slab of wax that Nick Cave hands to you himself. Straight to you.

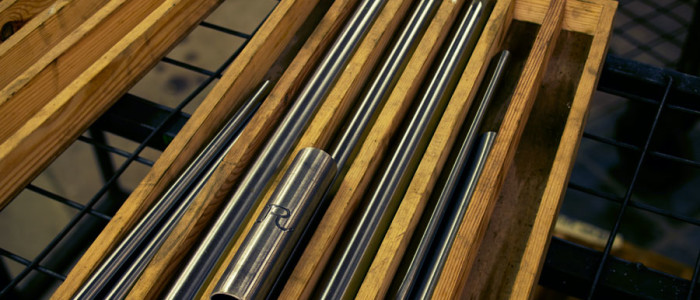

Where the vinyl record remains round, grooved and black, the steel bicycle’s tubes remain round, straight and flat. You can’t improve on what’s proven. What’s perfect. Only the touch of the hand of the artist can make each one unique, where things that are really just simple things (a record, a bicycle) can be themselves set apart by the signatures laid upon them by their creators, curating originality (Jagger, Jaegher). To say it’s pretty special to see your own bicycle being made, your name on the tubes as they come together to be joined forever by the heat of the torch and the deft touch of the electrode, would be a modest assessment. To finally ride it, might be impossible to describe.

@Ron

Definitely Ambrosio (pictured here)

Closeup Ambrosio

Hey all, I have arriving soon a Ritchey Swisscross frame set. What’s the deal with “framesaver” type applications of rust inhibitor for steel frames? Everyone using this kinda thing applied to inside of frame?

@ChrisO

+1 for the @The Grande Fondue and @ChrisO from me. I had a steel Ciocc until it was squished under a truck with me aboard (the bike didn’t make it). I now ride high end carbon and low end aluminium but miss the comfort and classic looks of steel. In a few months time I’ll be ordering a custom steel Shand Skinnymalinky (made in Scotland but not from girders) as a retirement gift to myself after 30 years in my current job. The carbon current#1 is comfortable, way lighter and the bike of choice for epic climbing or when I want to go fast, relatively speaking of course. The Shand will be the bike I ride on all day and multi day trips before I am forced to find another job to buy more bikes. I’ve ridden bikes long enough to know that there are very real advantages to all the frame materials for more than 0.1% of us.

In fact my first real mtb was a 1994 Marin Bear Valley SE, triple butted steel and an epic bike for a long day on the trails. Recently the frame has been rescued from the back of the garage, stripped down and prepped to be properly restored. Then the alu mtb risks being sold off because I know it won’t get used.

So, steel #1 in the future for me but when I have speed and / or epic climbing in mind it’s the carbon machine as 7.4kg is easier to haul uphill that 9.4kg. In the winter? Aluminium CX, mudguards with 28mm GP 4 Seasons all the way. Train heavy, race light.

@wilburrox

It’s a good idea, especially with a bike that’s going to see wet conditions. I just use a rust inhibitor spray (Rust Check) from an auto supply store; does the same thing at 1/4 the price. Some shops treat every steel frame before they let it out the door, so if you’ve ordered through a LBS they might do it for you.

@unversio

Amazing how a simple thing like a cable stop can have so much artistry.

@Teocalli

Yes amazing. Hate to miss NAHBS this year, but will not miss next year.

@TommyTubolare

Hold on a second here, you’re perpetrating the myth – I’ve had cause to ride a LOT of bikes in all materials over the years and one of the stiffest bikes I’ve ever ridden in any material is my Benson, which is made out of over-sized Pego-Richie Columbus steel tubes. We should all stop generalising for a minute and just accept that any frame material can be built soft, hard, stiff or flexy depending on the builder and the exact specifications.

@wilburrox

Need to overhaul the bike (The Sword) for this very reason — just to see what we see. Planning to send the frame to Velocolour in 2016 for paint and their full treatment inside and out.

@Oli

Hear ye, hear ye! Specifically chose Columbus MXL so that I “would feel everything” coming off the road. And also that my wheels would feel everything coming out of my legs and arms — power trans-fer-lation (fabricated word here).

@Teocalli

The picture of the whole bike didn’t draw my eye for long but I did dribble a little bit after seeing the close up.

@TommyTubolare

Were you riding Columbus Cromor or Gara ?? or Reynolds ??

@Teocalli

and how a cheap piece of plastic (the QR) can ruin a thing of beauty.

@Oli

I have ridden my fair share of bikes and wheels. My experience is just different to yours.

How much heavier were oversized tubes? Can you mold and layer up different kinds of steel like you can do different kinds of carbon? Are you trying to convince me that properties of steel as a material are the same as carbon? Clever carbon lay up and using the right kind of carbon in certain areas on the frame, like bb for stiffness or seat stays for comfort as an example, allows to build a comfortable and stiff frames without adding too much weight or sacrificing handling and durability. You can cut a steel tube to length and that’s pretty much it.

You can keep your steel and I will take a carbon and we’re both happy. More steel bikes for you.

As far as wheels go it’s the same for me. I’d take carbon wheel over alu wheel any day. That includes riding on cobbles.

@unversio

I didn’t and to be honest I don’t intend to. I usually move forward with my frame material choices. You can stay where you are or keep going backward if that’s what pleases you. Keep your toe clips and I will continue using my speedplays.

@brett

Understood. Sorry to hear that. Well at least it didn’t get lost in the transit and good they sent it back without waiting for you to pay. Sometimes they keep the goods forever.

@tessar

With the vast range of stock frames available these days, almost any “custom” build can be matched with an effectively identical stock frames,

Agreed. Not to mention the amount of stems, handlebars and seatposts.

@TommyTubolare

I’ll bet you consider yourself an elitist.

I have a custom carbon frame because I am of the 0.01% of people over six and half feet tall. Pictures when I get my Cafe Roubaix Carrefours wheelset.

Steel is the reference point for all other frame materials. Period. Every one of the other materials has used steel as a barometer to extol their virtues. Steel has it all wrapped up in one nice package. It is the “frame” of reference.

@wilburrox

I would use some type of frame saver, cheap peace of mind. Plus you don’t want a post seizing in the frame, because it will happen especially if you don’t remove and grease the post occasionally. Most good steel frames the main tubes and rear triangle are usually sealed so it’s just the seat tube you need to worry about

You cannot tune the ride characteristics of other materials like you can a custom steel frame. My last custom steel frame, the builder choose tubing type and thicknesses and other various details, riding style etc. to build a frame tuned to how I wanted the bike handle and ride, and that is exactly what I got, your not getting that with other materials

@Roger

You can’t braze a sealed tube. Air pressure from the heat spits the hot silver or brass out (usually in your face) and leaves a starved joint. It’s possible to braze the vent holes closed after building the frame, but I’ve only ever seen that on forks, never on internal holes or even a rear triangle. Too much cleanup and it just seals in moisture rather than letting the frame breathe.

@Brett

I have a good record player, and I just recently completed my Led Zeppelin collection on Vinyl – the final bit being a perfect UK pressing of Zep I. There is some noise on the record, but its much more dynamic than my digital copy which I stream from my phone or laptop.

The record is more fun to listen to, but it also means I’m flipping the record every 30 minutes whereas I can hit shuffle on my library and hear music I forgot I bought.

Each has their place and on any given day is the better choice.

As this applies to Rule #12, no one has to guess. We need bikes of all shapes and sizes, in all materials and disciplines.

@TommyTubolare

I don’t know how you got that I was somehow criticising other materials because I’m not at all! Even though my steel frame is stiff, it’s certainly not light, so I’d never claim that it’s “better” than another frame made of a different material. I agree entirely that carbon has many benefits that steel can’t duplicate, and I’m not foolish enough to try and claim that any material is superior in every application anyway.

My (I thought clearly stated) point is that geometry isn’t the only predicator of ride quality; that materials, dimensions and finishing kit also have an effect. I don’t think there can be any rational dispute about this.

@pistard

Maybe I should have used a better term than sealed, I do know that the front main tubes on my custom Indy Fab frame are closed off.

@Haldy

About brazing vs. TIG welding : we use brazing for small attachments such as cablestops etc. and our lugged frames. The lugs will make the joint strong enough and minimal weight is less important with these frames. Technically TIG welding is however far superior. The joint is stronger and less material is added so it is lighter as well. TIG welding (especially the very thin tubes and even more stainless) is a lot more difficult, requires very precise mitering, equipment is more expensive and the learning process takes far longer.

@Roger

Yes, my IndyFab is like that too – I haven’t quite figured it out!

@wilburrox

It all depends on how and how much the frame will be used and where. If you ride a lot in the rain etc it might be useful to spray some WD-40 or similar inside from time to time. Grease between the seatpost and seat tube will keep most of the water out if redone regularly.

@frank

I’m envious….. I have I, II & IV…. I have a ways to go

@Jaegher

Apologies if my post implied any knock against TIG welding. That was certainly not intended. I am just a very excited devotee to Don Walker’s work as I have 4 of his frames. He prefers filet brazing so and all of his frames are constructed as such( although he does do lugged if requested). I have a pair of TIG welded beauties in my fleet currently a matching TI and Steel set of frames made by Seven. I also await another TIG’ed beauty…a Big Leg Emma from Dario Pegoretti

@Jaegher

I sure appreciate that perspective. Thank you. When speaking with the folks at LBS I’d said I wanted to see the frame first before we did anything. The thought of gunking up the frame, even if on inside, kinda permanently ? But I’ve not seen the stuff applied. My bikes do get wet and muddy and they also get regular TLC. This will be the CX bike for ’15 season. I have a 30+ year old CroMoly frame/bike that has never been treated and is in decent shape.

@Teocalli

What collection of tubes will steel#2 be made from? Modern large diameter thin wall? Retro skinny and lugged? I’m interested to hear the fourth data point. I’m betting it will be between the two carbon points if its modern stuff.

@Roger

I just snorted my coffee. Choosing tubing type and thickness is just about the peak of what you can vary on a steel frame, which is nothing compared to the possibilities that engineered composites have. Claiming the opposite is just laughable.

@Oli

To that point, the wheels are the item that impacts the ride more than any other single factor; I had Ksyriums on my TSX and is sucked the life out of the frame. Putting some 3x tubs on there turned it into a butter yet lively ride.

Same for my carbon frames; I have climbing wheels, flying wheels and 3x box sections (Golden Tickets) and all three completely change the nature of the machine.

Is it difficult to keep carbon in good condition?

@Oli

I don’t know either Oli, but if I did my apologies.

On the other hand I never said that geometry is the only important thing because it clearly isn’t.

All I did is noticed in this thread that steel was somehow given these superior properties that actually cannot be applied to steel, hence my disagreeing posts.

@unversio

Your bet couldn’t possibly be more wrong. You should try less betting and more thinking.

@Roger

I hope you’re joking.

@DavidB

It’s not custom, it’s the NOS Pinarello Sestriere that I posted some Pics of a while back under Bikes. So it’s lugless and a mix of tube shapes mostly round with a formed downtube. Tubing is Pinerallo’s own spec from that era.

@tessar

not really laughable, at what cost are those possibilities with composite? I have to disagree. Anyone here have a custom composite bike who would care to share?

This is sounding more and more like a cycling news dot com forum thread rather than just pure appreciation of what is a massively impressive piece of equipment.

Carry on

@brett, more photos please

@TommyTubolare

joking about what oh great one who seems to know everything? That I feel steel is great material for custom frames over composite? Composite is a great material but not really to cost effective, do you have a custom composite frame? do you have first hand experience with a custom builder engineering and custom tuning a composite frame?

@wilburrox

Don’t put anything on the inside of the frame. With some normal maintenance a high quality steel frame will last forever.

That stuff is really nice to look at/admire/insert whatever here. While I can honestly say that I love my carbon Trek, it’s definitely a high performance “appliance”. No soul or element of special. It just simply “does”. Maybe someday when I’m over playing with cars on racetracks I’ll have that money and time freed up to allow me one of these steel masterpieces. Best of both worlds, right? The carbon fitness tool…and the steel “appreciation for cycling” piece.

@Roger

First of all, the cost of custom carbon is, proportionally, the same as the cost of custom steel over stock. IE, for the price of a high-end stock frame you can also get custom. Argonaut, Parlee, Guru etc charge about what you’d pay for a top stock frame – just like most custom steel builders charge about what you’d pay for a top steel bike.

But that’s beside the point. On virtually every carbon frame sold stock, somebody did more manipulations in terms of material engineering than any steel frame, stock or not, could ever hope to match. You can have more stiffness where you want it, and more compliance where you want it, both at the same time from the same tube. Steel, by design, can’t do that since it’s not anywhere near as anisotropic as carbon fibre. The fact that on a custom steel frame you get to choose between A and B doesn’t mean it’s better than a carbon frame where the engineer had choices between A and Z – it just means you have to choose which frame to get.

P.S: I’m still riding aluminium, I don’t have any post-purchase justification bias going on here. Stick a good tyre and latex tube on a ho-hum alu frame and it’ll fly.

So we’re all agreed that great frames can be made out of any material, depending on the builder and what is required from said frame? Good.

@Oli

Aye, and I’ve found myself with some serious Alu-bone for a Bowman Palace.

Agreed, its all personal preference on frame materials

Agreed, that different sets of wheels, tubes and tires can transform the ride characteristics of any bike dramatically custom or not. Its almost to a point where a custom frame of any material should also be designed with consideration as to what set of wheels the rider is going to use because the ride characteristics from one wheel set to another can be very different, but that is a discussion for another time, lol

@tessar

Comfort is a complex subject. Positioning is without one of the most important aspects. It may be even more so for your performance. A custom geometrie may or may not be needed for you depending on your body measurements, body limitation (flexibility and other body issues), planned use, etc… It will guarantee you a good handling (balance on the bike) for you position. Other specs can of course be included at the same time (tire spec, stiffness, limit spacers,…).

Tire width, type and pressure also influence comfort a lot and so will your contactpoints : seat (limit local pressure points), bar shape and bartape, pedals and shoes.

I try not to include wheels as other qualities as far more important with these depending on your ride ; aero / side-side stiffness / weight / durability / wind sensitivity /… This being said, I will not use my 50mm high carbon wheels at Roubaix ;-)