Reverence: Cinelli Forged Quill Stems

Reading articles and viewing accompanying images here you'll notice a common piece of equipment on a large number of the classic riders' bikes. The Cinelli forged quill stem. Cinelli must have had one hell of a business model going in the 60's, 70's, and 80's because it seems their stems and bars were the must haves on many a pro-rider's steed. Yes, there were others such as 3TTT, ITM, Campag, and Shimano. All worthy manufacturers of quality equipment. But my extensive quantitative, and thus conclusive, research on the subject of classic quill stems has determined that Cinelli stems far outnumbered the others in the pro peloton.

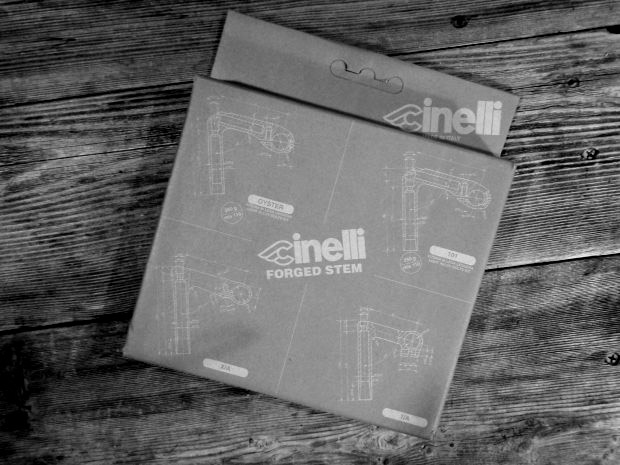

The people of Milano, it happens, know something of the elegant juxtaposition of form and function. Who knew? Here's what they had to say to any prospective consumer who happened to pick up the package in an LBS of the time:

Cinelli stems have been recognised fore more than 40 years as the result of the most advanced and selective production cycles. The perfect construction, accurate finishing and high reliability are the reasons that have led to the most famous champions to choose Cinelli. All the models are produced by hot forging of extruded bars in 6082 alloy. This procedure guarantees structural compactness and more favourable fibre orientation. Successive phases of machining assure the precision of the clamp and the shaft diameters, guaranteeing extremely low tolerances.

You've probably noticed a couple of typos in the above quote. They were left in to convey the challenge some Italian marketing worker must have had translating the Italian from the other side of the box into English. Had it been a seamless translation imparting the beauty that the Italian written word surely does, there probably would have been even more consumers drooling on the box. No matter, drool on the box. I'm certain most of these boxes were not placed back on the shelf at the LBS. They were most certainly discarded after the consumer replaced their old stem, cables, and bar tape.

I chose a Cinelli stem for my most recent build. Though I've barely ridden 200k on the bike in the two weeks since it's rebirth, I have to say, they've been a glorious 200k in large part due to the Cinelli stem peering up at me on each ride. I had the choice of four models Cinelli made right before they and other manufacturers began focusing on the modern threadless stem. At the time one could choose from the Oyster, 101, X/A, and 1/A. The Oyster was Cinelli's “openable” model with a double pivot hinge. The 100mm Oyster weighed 260 grams and came in anodized silver or black. The 101, the stem I chose, was forged from 7075 aluminum and is the lightest of the four at 250 grams in 110mm. However, I did not choose it for its weight. I was drawn to the forged grooves in the front of the stem similar to the fins on a cylinder head. There was also the X/A which seemed to be the choice of most pros perhaps because at 290 grams for a 110mm it was the strongest. Finally there was the 1/A which came in the widest range of lengths and whose clamp faced the road, as opposed to the others, whose clamps faced the rider.

All four of the stems of this vintage had a few things in common. They all had expander bolts as opposed wedge nuts, 73 degree angles, and 26.4 clamp diameters. This last piece meant that the consumer was also tied to buying Cinelli 26.4 diameter handlebars. Those bastards! Making us buy a beautiful, functional stem and then having to buy gorgeous Cinelli bars to go with it whose curves rival those of any Bella Donna.

[dmalbum path=”/velominati.com/content/Photo Galleries/m.carlson@vcc.edu/Classic Cinelli Stems/”/]